Managing stock on the move feels promising but shifting to mobile inventory management isn’t always smooth sailing. Hidden pitfalls can drain efficiency and spike costs if you don’t tackle them early. So, what’s holding businesses back from unlocking the full power of enterprise mobility solutions? Let’s unpack the top five challenges — and exactly how you can stay ahead.

-

Data Silos: The Silent Efficiency Killer

How often do you wonder if your teams see the same data in real-time? Data silos are notorious for blocking the seamless flow of stock information across departments. This disconnect breeds miscounts and missed orders.

Fix: Cloud-based back-ends are non-negotiable. They ensure every device, from basic barcoding units to advanced RFID handhelds, syncs up instantly. Did you know that according to Statista, nearly 94 percent of companies already rely on the cloud for better data access? Think about it — are your systems talking to each other?

-

Device Compatibility Chaos

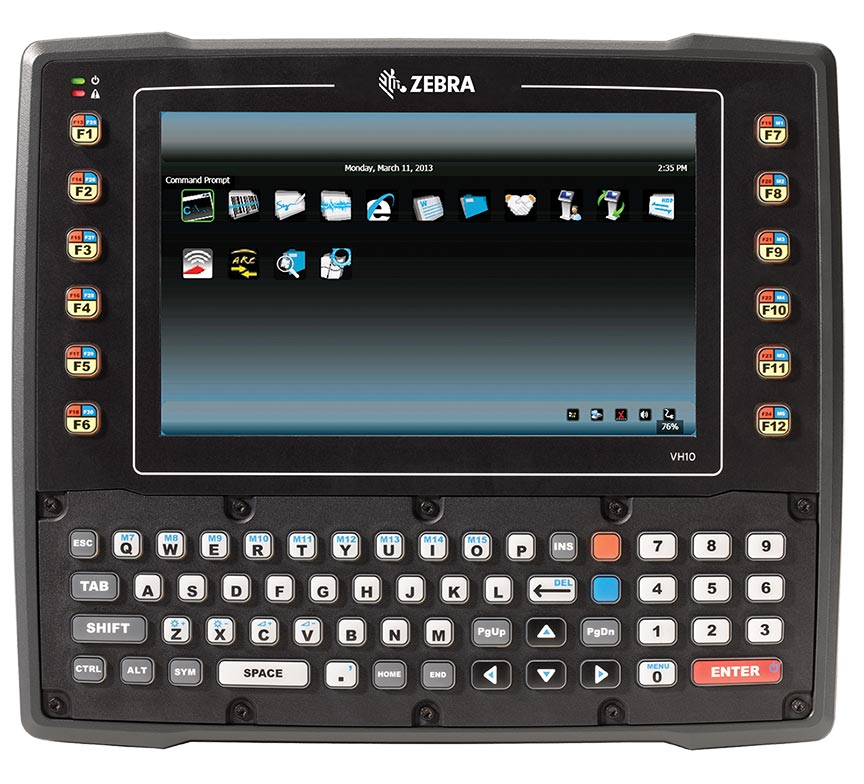

Are you struggling to pick devices that can survive your warehouse floors? The wrong hardware triggers breakdowns and replacement costs. One size rarely fits all when it comes to rugged mobile devices.

Fix: Select devices built for your industry’s wear and tear. For instance, ruggedized scanners with drop protection or moisture resistance can save you thousands in downtime. 5th Wave is right here with its range of options to cater to all your demands — from handheld barcode scanners to smart RFID solutions. Why compromise on durability when affordable, scalable options exist?

-

User Training Woes: Are You Doing Enough?

Even the smartest mobile inventory management tools flop without confident users. Do your teams find the interface intuitive? Or are they stuck battling with confusing screens while orders pile up?

Fix: Invest in clear, role-based training. Keep interfaces simple and workflows logical. Consider gamified learning modules to speed up onboarding. This proactive step bridges your team’s tech gap, ensuring that your enterprise mobility solutions perform as promised.

-

Connectivity Hiccups in the Field

Picture this — your field team scans a shipment but the system won’t update because the signal dropped. Annoying, right? Weak connectivity can lead to duplicate entries and costly errors.

Fix: Choose inventory apps that offer offline modes with auto-sync capabilities once the network returns. Pair this with reliable mobile networks and signal boosters for dead zones. Have you tested your connectivity strength where it matters most?

-

Balancing Affordability with Scalability

Here’s a big question: How do you expand your mobile system without breaking the bank? Many businesses stick to outdated manual processes because they fear the upfront costs of modern upgrades.

Fix: Partner with a solutions provider that offers modular options. Scale up your mobile inventory management capabilities gradually — whether it’s adding new barcode scanners or upgrading to RFID tracking. This pay-as-you-grow model keeps budgets tight while future-proofing your operations.

Ready to Turn Challenges into Competitive Wins?

Now you see how these common roadblocks can sneak up on even the best-run warehouses. But with the right enterprise mobility solutions, you can turn these into your strongest points. Remember — the real magic happens when your systems, devices, and people work in perfect sync.

If you’re rethinking how to elevate your mobile inventory game, ask yourself: Are your data streams open? Are your devices fit for purpose? Is your team ready for tomorrow?

5th Wave is here to bridge every gap — from rugged hardware to advanced RFID systems — tailored to your unique industry demands.

Let’s make your inventory smarter, not harder. Want to see how this can work for your business? Reach out today — you’re just one smart decision away from hassle-free stock control.